How to Build a Window Seat With Hinged Lid

Building a Window Seat with Storage in a Bay Window

Building a Window Seat with Storage in a Bay Window

You know when you dream about the finished product on something that you've been planning for a long time? And then you finish and your dream becomes a reality? And you think to yourself, am I still dreaming? All those sentiments and more have been going through my head since I finished the building this built-in window seat with storage in our bay window. This window seat is divine! In fact, I've begun calling it the Queen's seat in the hopes that it will deter any male folks from claiming it in our household.

Several of you have asked for the tutorial to build the window seat. I have that for you, but I want to mention that this is a slightly more advanced project. Halfway into writing this tutorial, I realized there was no way I could show you each and every cut, step, and trick without this being the world's longest blog post/tutorial. If you have some basic carpentry skills (you know how to hammer, nail, use some power tools and you know how to attach a 2×4″ securely to a wall), you should be able to handle this. With that being said, I do want to offer any help if you should have any questions during the process of building this bench, please feel free to email me and I will do my best to help you.

I also want to mention that I did have to move the HVAC vent forward so it came out the front of the window seat. Here's the tutorial to move a floor vent. I do want to caution you against building over a vent. We have a bookcase that was built over the register and the wood inside grew mold because there wasn't enough force to blow the air and moisture out the front of the bookcase. Just a warning, don't take the easy way out.

Basics for Building a Built-in Window Seat in a Bay Window:

Materials:

( I've included affiliate links for your convenience. I earn a small percentage from a purchase using these links. There is no additional cost to you. You can read more about affiliate links here .)

(Subject to your own window dimensions and needs.)

- 6 – 2x4x96″ studs

- 1 – 4'x8′ MDF sheet

- 2 1/2″ finish nails

- 4′ Piano hinge

- 12d Framing nails

- 2.5″ Wood screws

- 3″ window stool

- 5″ window stool

- Drywall for front of bench

- Construction glue

- Cove molding

- Corner molding

- Quarter round molding

Optional:

- 3/16″ plywood for floor inside storage bench

- Dremel with metal cutting wheel

Tools:

- Jigsaw

- Miter Saw

- Circular Saw

- Drill

- Hammer

- Kreg jig

- Level

- Framing Square

- Pencil

Instructions:

Remove any baseboard molding and window stools and other molding in your work area.

Build a small framing wall with 2×4 lumber that fits perfectly in the front width of the bay window. The wall should be approximately 15″ tall. The finished height will be 17″ tall after the lids and reinforcing studs are added. After adding a cushion, the height will be a standard 18″ chair height.

Set the framing back to allow for the thickness of drywall.

Attach the framing to the floor with screws or framing nails. Toenail (nail in at a 45 degree angle) the ends of the framing into the wall.

Attach 2×4 studs to the back of the bay window. Make sure that they are level with the framing wall.

Measure the distance between the front of the framing wall and the back wall. Cut three 2×4 supports to this depth. (You will notice that I have an outlet that still has to be moved by the electrician. By code, you cannot cover an outlet or even a junction box. The remedy was to move all the wiring to the front of the window seat.)

Cut and attach 2×4 boards on the angled walls of the bay window and stop them at the front framing wall. This support is at the same height as the 2×4 supports that you just cut, so be sure to attach it 1.5″ above the framed wall. Next cut a 2×4″ board to fit between the side wall and the first support board. Repeat for the opposite side.

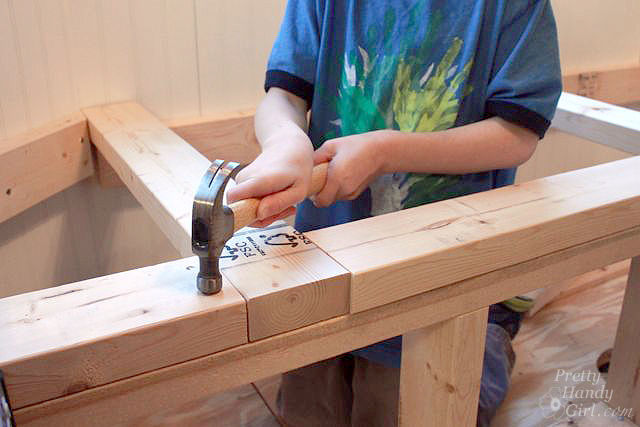

Cut two more 2×4 boards to fit between the support 2×4's. Make them snug, this will reinforce the support boards and the framing wall. Hammer these boards to the top of the framing wall using framing nails.

Cut two more 2×4″ boards that will sit on top of the boards attached to the back of the bay window.

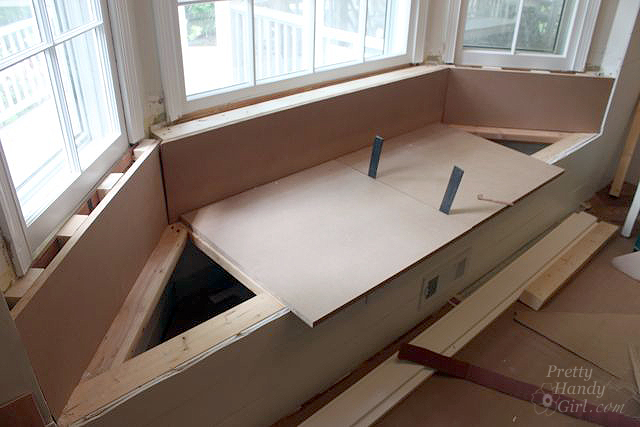

Nail these two board into place. They will sit on top of the secured cleats at a perpendicular angle. You bench should look similar to this, when viewed from above:

Before you attach those support 2×4's permanently, you might want to consider adding a finished flooring inside your window seat. Especially if you will be using it for storage. (I installed tar paper on top of our subfloor and screwed thin plywood pieces to the floor.)

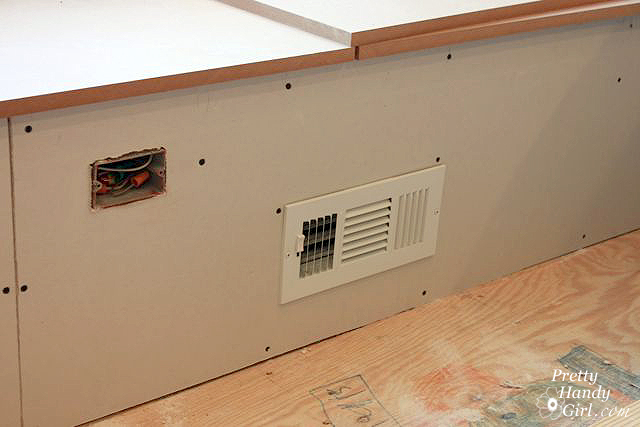

You can now attach those support 2×4's with framing nails. Nail them to the front framing wall and the back wall cleats. This is also the time to move any wiring and HVAC. (As you can see, the electrician ran the wires for the new outlet, and I installed the new vent into the front of the bench. Tutorial at a later date.)

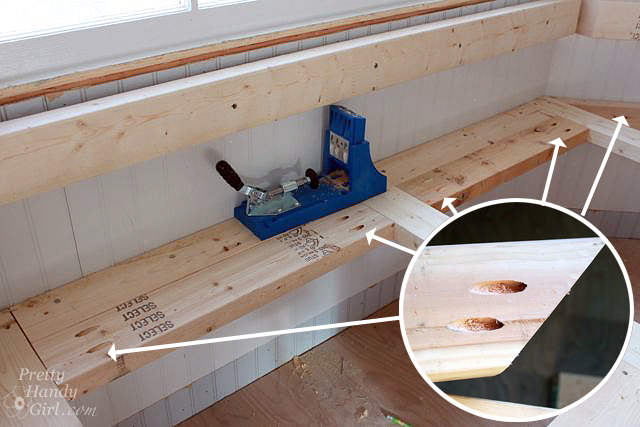

At this point in my build, I decided I wanted a shallower seat and wanted to bring the back forward a little, so I added additional horizontal supports between the front to back supports. I used a kreg jig (tutorial for using a kreg jig) to create pocket hole joinery to secure the supports.

I also added more support to the side angles using 2×4's with pocket hole joinery on the ends.

Frame a small support wall for under the large middle window. Cut vertical studs to frame the back support for the side windows. This allowed me to have more width overall, but a shallower seat. (If you have a sharp eye, you'll notice I ditched the idea of the horizontal supports in the previous picture.)

Drive screws into the back support frame to secure it to the wall and the bench supports. Nail or screw the other 2×4's (under the smaller windows) to the wall.

Add drywall to the front of the bench (Tips for installing drywall. How to mud a drywall seam.)

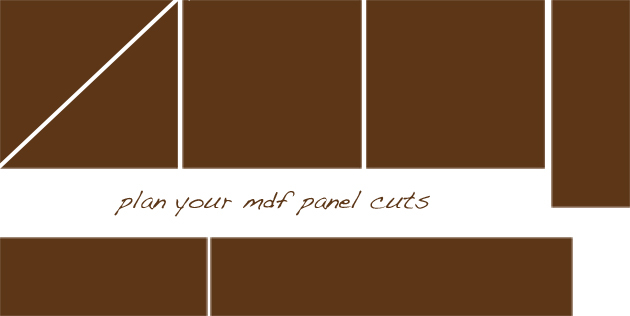

Time to cut the MDF panels for the bench top and back. It is a really good idea to map out your cuts ahead of time. All my panels fit on the one sheet of MDF, but it was a tight fit.

Unless you have a helper, the best way I found to cut a heavy MDF sheet is to prop it up on 2×4's. Then clamp a straight edge to the sheet. Use a circular saw to make your long rip cuts. Then you can use the table saw or continue to use the circular saw to make the smaller cuts.

The shims in between the two seat panels (shown below) are holding a slight gap between the seats while I measured the triangular spots. This will allow the panels to expand slightly after I paint them.

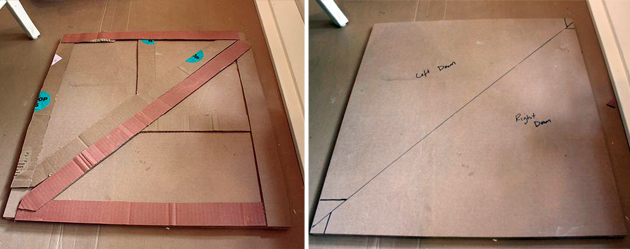

Speaking of measuring those side triangular spots. I learned a really cool trick from the countertop installers.

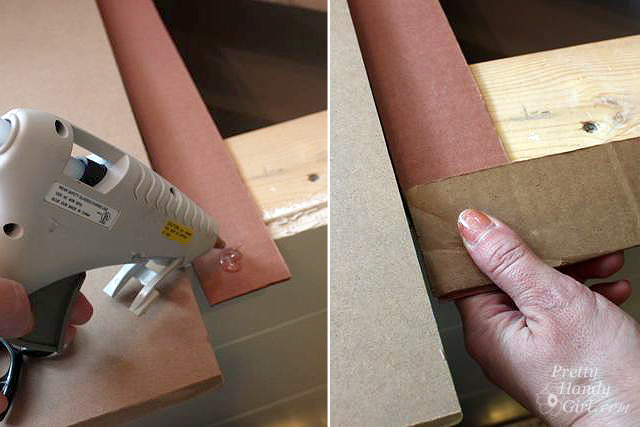

They used thin strips of plywood to create a template. I used strips of cardboard to do the same thing. Simply cut cardboard strips and line them up against the perimeter of the triangle.

Use a hot glue gun to join the strips at the corners.

Remove the templates and trace them onto the MDF board. Cut them out with a jigsaw. Be sure to label which side is which.

Layout the MDF panels on the bench. Attach the back panels with finish nails (drive nails into the studs behind it.)

The bench should look something like this (I still needed to trim down the seat panels, but wanted to make sure they were flush with the side panels.):

Cut the two middle seat panels down to size and route all the front bench panel edges with a router and a rounded bit.

Use a jigsaw to cut the profile for the new window stools (if you saved the old ones you can use them as a guide). Use smaller 3″ stools for the sides and a 5″ for the middle window. Overlap sections and mark where they overlap to get a tight seamless fit.

Nail the stool into the top of the back support with a finish nailer. Caulk all edges (except where the stool meets the window sash.)

At this point in the window seat build, we ran our plank walls up the sides of the windows, and capped them off with Howe casing. You can read about installing plank walls in this tutorial.

To save money, I purchased a long piano hinge and cut it in half with a metal cutting wheel on a Dremel. You could purchase two smaller hinges if you don't want to cut the hinge.

Attach the piano hinge to the back support and the top of the lids using the screws provided with the hinge.

Glue and finish nail the side triangle panels to the supporting 2×4's.

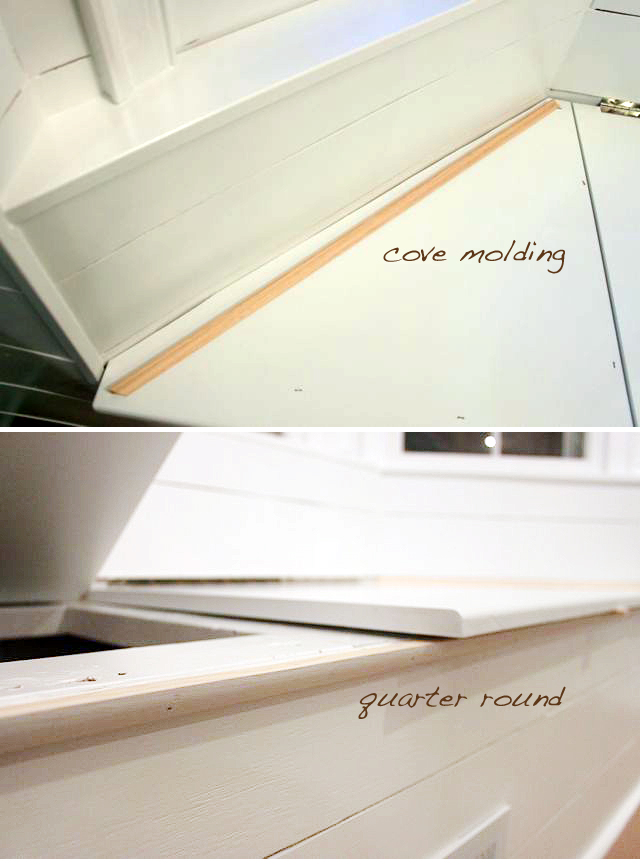

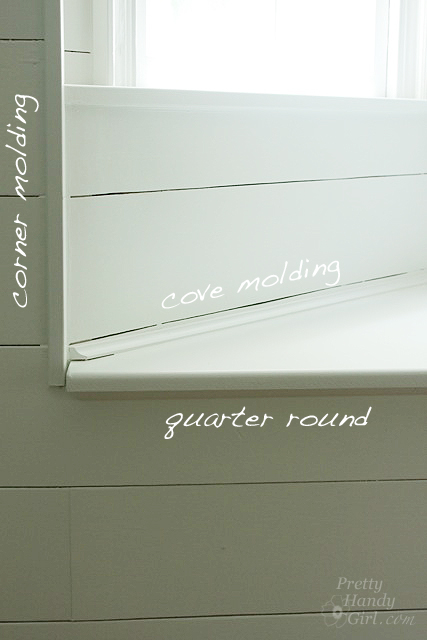

Add cove molding to cover the gaps on the side of the triangular panels. Add quarter round just under the lip of the seat panels to finish off your bench.

You can add corner molding on the sides of the wall where it meets the back support.

Wood putty all nail holes. Let dry, prime and paint.

The bench has loads of storage inside.

I will probably add some type of lift support at a later date.

Here's the bench before I made the cushion.

Ahh, adding a custom bench cushion with piping was the way to go. Learn how to sew your own bench cushion with piping here.

I'm really enjoying this seat fit for a Queen!

The extra floor space in our kitchen helps make the kitchen feel bigger.

The ledge under the windows is wide enough for me to add plants or herbs if I want.

What do you think? Do you have a bay window that is dying for a window seat? Now you can add one!

Like this post? Here is a collection of 10+ Dreamy Window Seats:

Like this post? Here is a collection of 10+ Dreamy Window Seats:

How to Build a Window Seat With Hinged Lid

Source: https://www.prettyhandygirl.com/building-a-window-seat-with-storage-in-a-bay-window/

0 Response to "How to Build a Window Seat With Hinged Lid"

Post a Comment